1. Paper cup production process

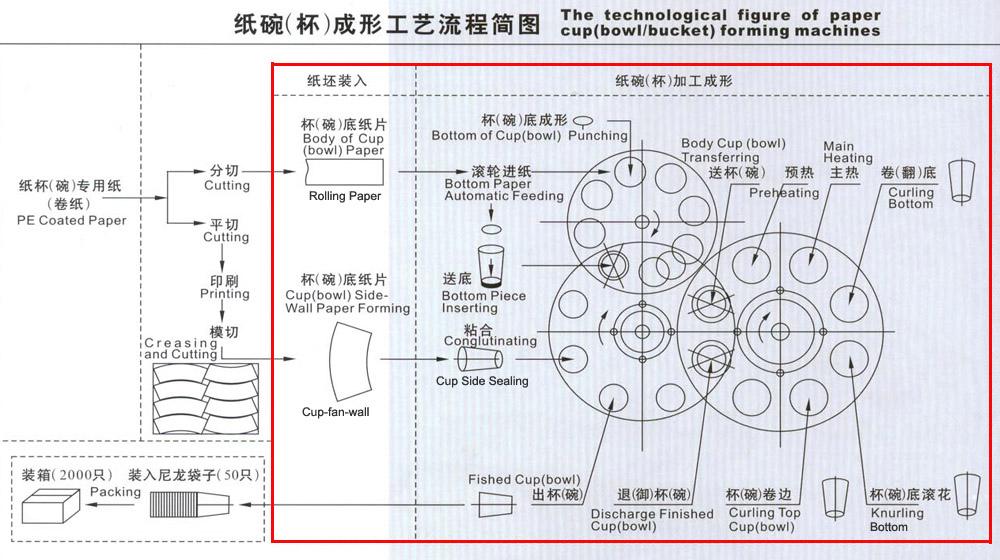

From base paper to packaging paper cups, the following processes are first performed:

1. PE laminating film: use a laminator to place the PE film on the base paper (white paper). The paper on one side of the laminated film is called single-sided PE laminated paper; the laminated film on both sides is called double-sided PE laminated paper.

2. Slicing: The slitting machine divides the laminated paper into rectangular paper (paper cup wall) and net (paper cup bottom).

3. Printing: Use letterpress printing machines to print various pictures on rectangular paper.

4. Die-cutting: Use a flat creasing machine and a cutting machine (commonly known as a die-cutting machine) to cut paper with outstanding graphics into paper cups.

5. Checking:Check the bonding effect of the bonding place, whether there is any direct bad condition, the bonding strength of the bottom of the cup and the bonding is suitable for tearing and pulling, and if there is no hair pulling directly, it is suspected of leaking the cup , subject to the water test.

5. Forming: The operator only needs to put the fan paper cup and cup bottom paper into the feeding port of the paper cup forming machine. The paper cup forming machine can automatically feed, seal and flush the bottom, and automatically form the paper. Various sizes of paper cups. The whole process can be easily operated by one person.

6. Packing: Before sealing the carton, the operator should randomly check the quantity of small packages. After the sampling is correct, cut out the product certificate or product drawing and paste it on the upper right corner of the left side of the carton, and fill in the job description in the box. No., date of production, and finally sealed and stacked neatly in the designated location.

2. Paper cup customization

The appearance and model of the disposable paper cup can be customized according to the different needs of customers.

Post time: May-10-2023